At its simplest: A circle is a … closed curve that divides [a] plane into two regions: an interior and an exterior. But it is so much more than that. One of the more marvelous properties of the circle is that, by definition, all radii are perpendicular to the circumference. Though seemly obvious, this has the convenient side-effect of transferring pressure, which acts outwards equally (i.e. along all the radii simultaneously) over the surface area of its containing vessel, into two force vectors that are perpendicular to each radius and tangent to the circle at all points around the circumference. The net result is that the pressure is converted into pure tension: rather than bending, the circular ring just wants to get bigger, elongating the material. Because this happens to be the way in which metal is the strongest, it is also the most efficient way in which to use it, requiring the least amount of material to contain a given pressure. Which is, of course, the reason that pipes and other pressure vessels are round (or, more ideally, spherical, but don’t get me started on spheres).

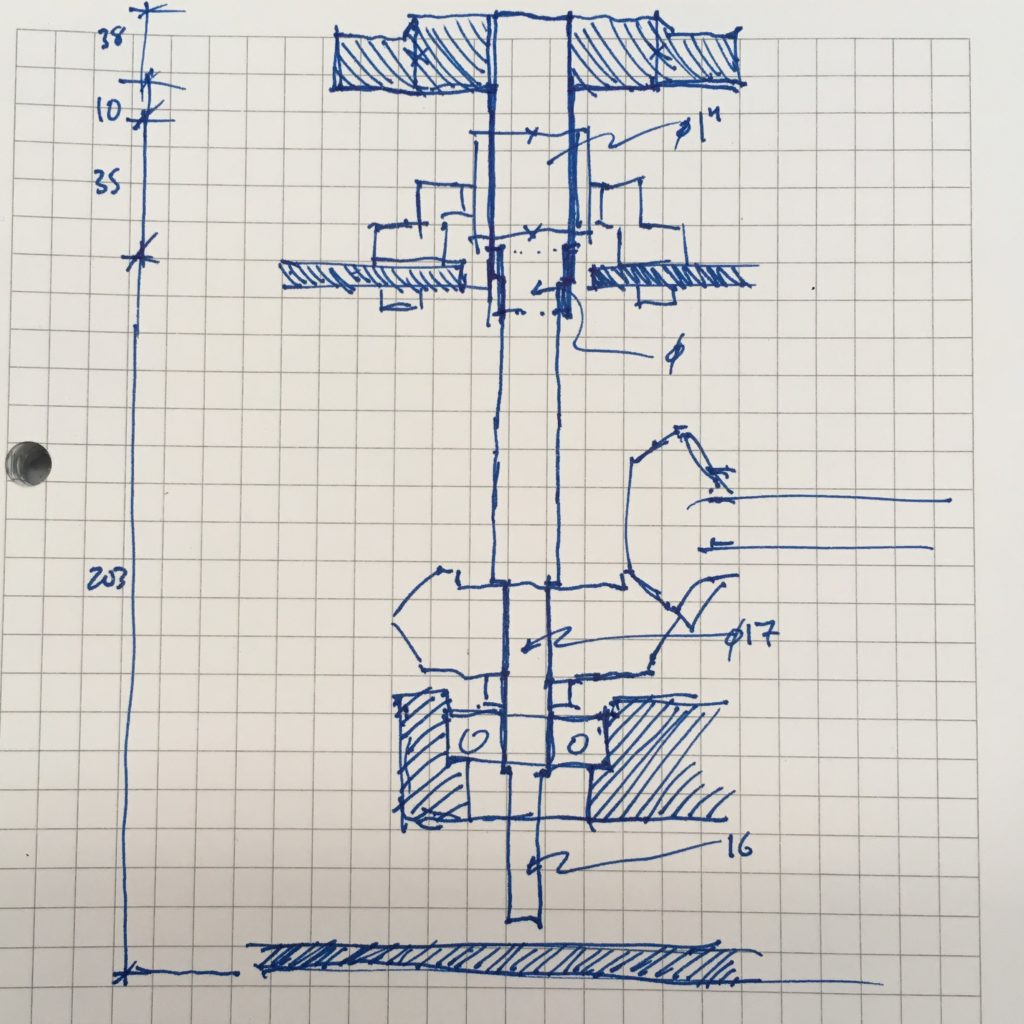

In the interim, I caused the translocation of a low-quality 1″ bearing from its previous resting place to my doorstep in exchange for a small amount of the most widely-known social construct most often referred to as money. And I made a plan.

The shaft is made from the same cold-rolled steel stock that the lever handles were machined from.

The crown gears have grooved hubs so that they can be keyed to their shafts but I had no key stock on hand. I cut some out of a piece of scrap – which was only somewhat quicker than going all the way to the specialty hardware store – who may or may not have had any (“Did you say ‘metric’ key stock?”).

Milling the slot in the shaft is a lot easier than cutting the groove in the hubs :)

Ah yes. I love it when things fit first time.

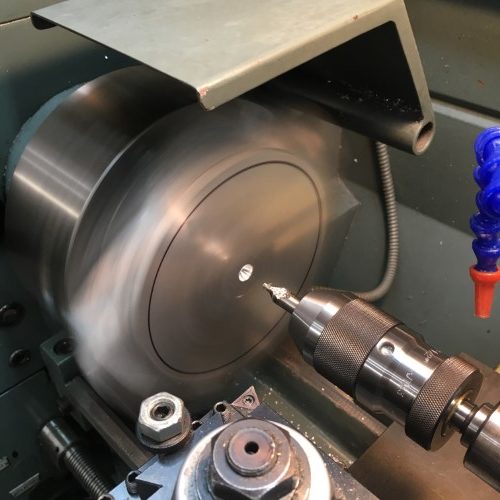

The other motivation for using the big cast iron face plate from the lathe is that has the same mounting system as all the other lathe chucks. So rather than mounting the face plate directly to the shaft, I am making a back or adapter plate from some mic6 aluminum (that has been patiently and unknowingly waiting for this day) so that all the other chucks will fit the turn-table.

Test fitting the back plate to the shaft.

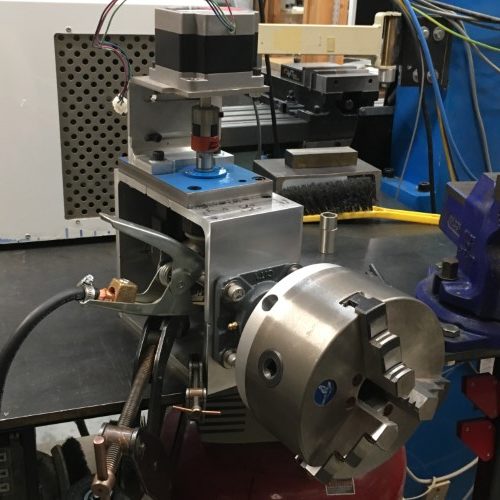

Things are coming together.

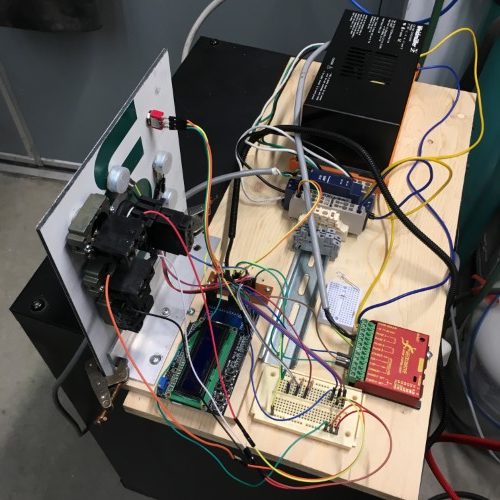

Now we just need a nice neat control system, which I absolutely promise to clean up and put in a proper box very very soon.

But for now, I can’t wait to give it a test drive.

And so we return to where we started; It always comes back around. Ouroboros: the snake that eats its tail.