Illustration by Pervprude

It is high time for more porridge!

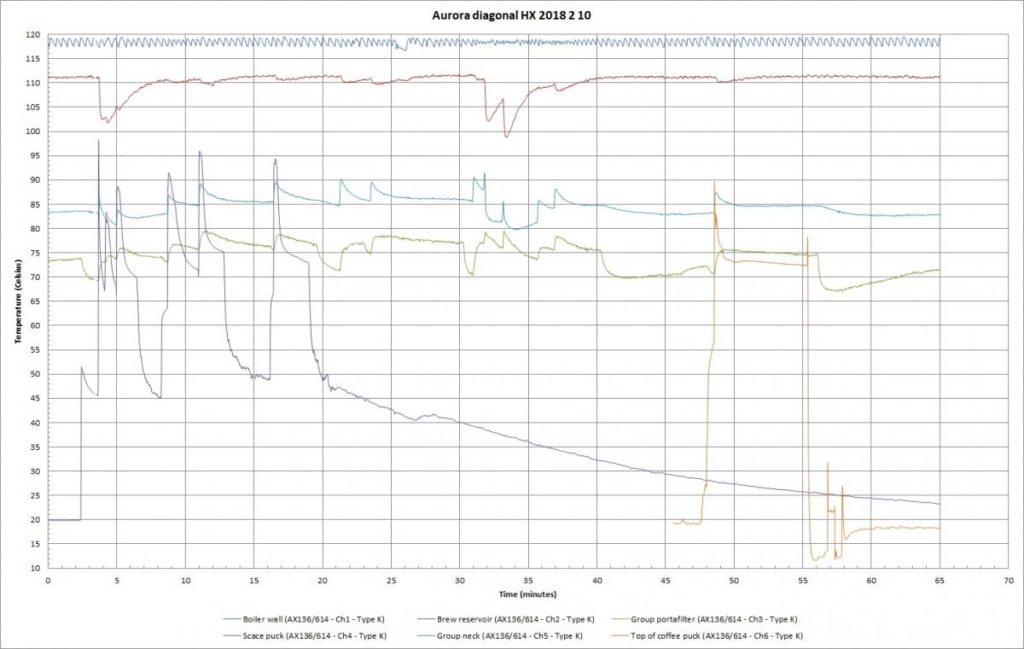

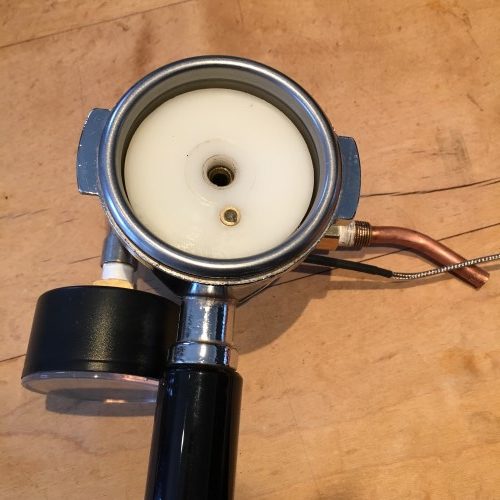

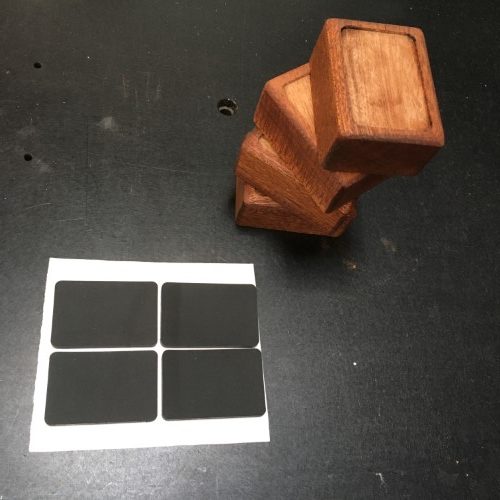

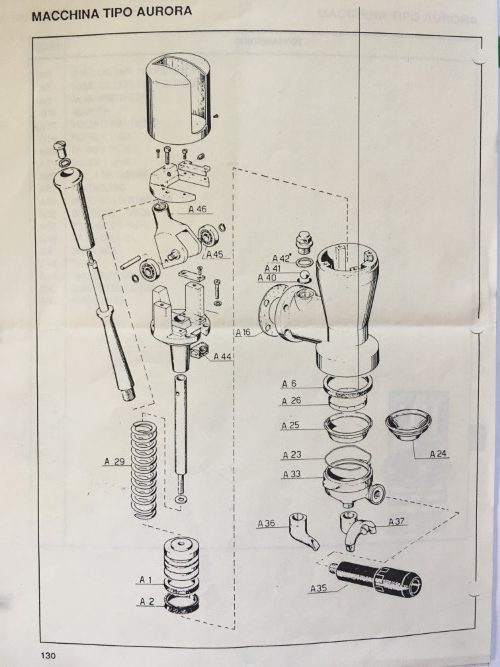

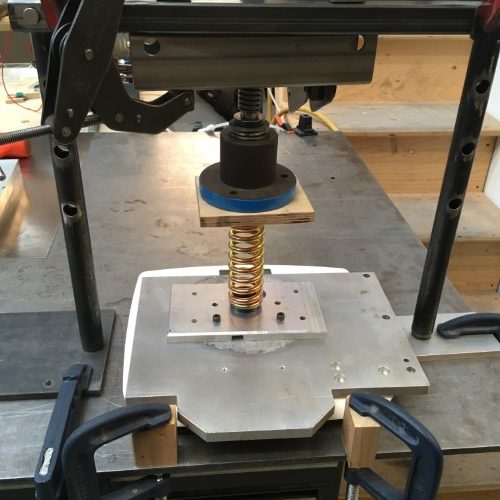

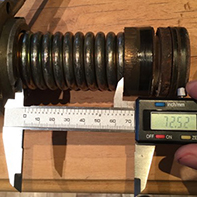

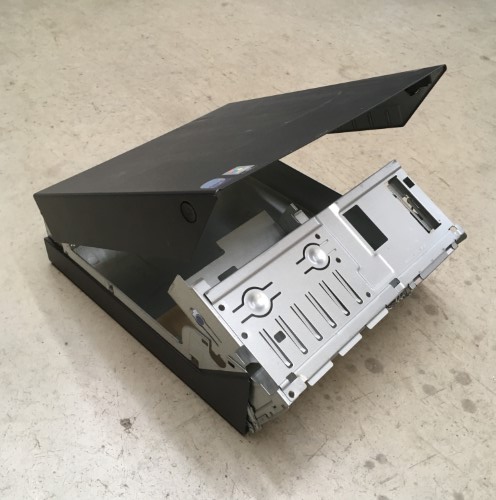

Several days after I did the first tests, it occurred to me that the horseshoe tube that I had made when I built the boiler was not the same as the one in the Brugnetti boiler. I wasn’t really thinking that hard about how a heat-exchanger actual works while I was making it. So I took apart the boiler (again). This is the original tube, nicely blackened after a few months of service:

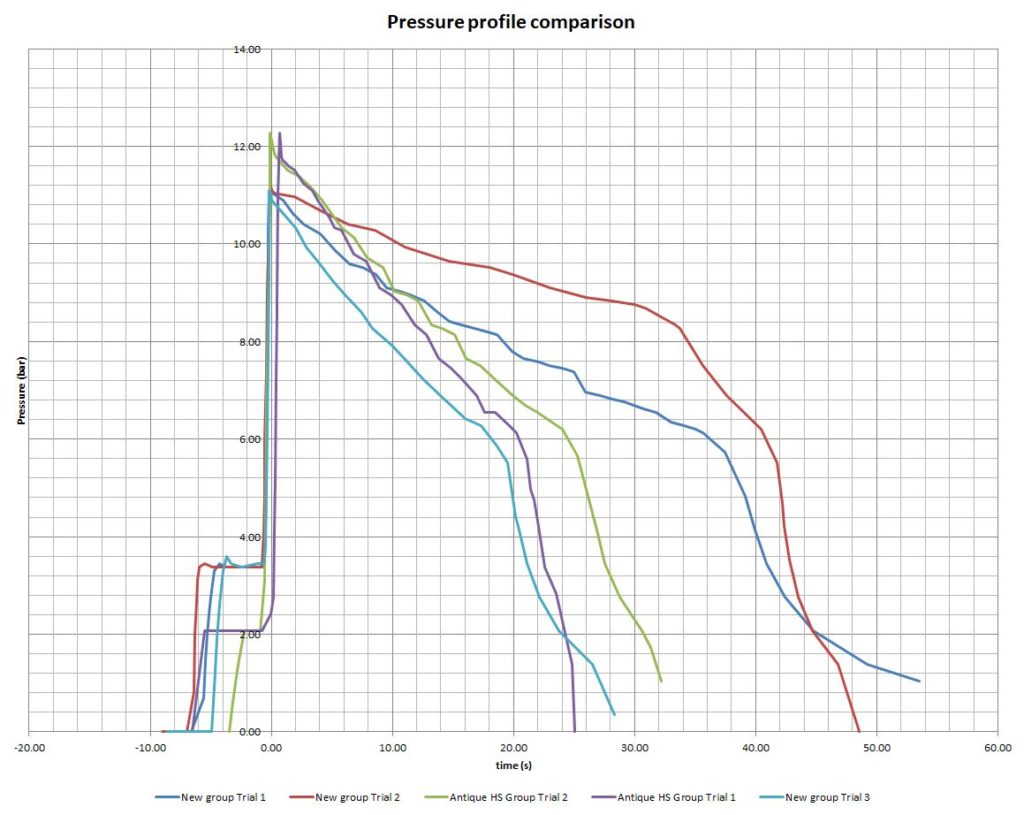

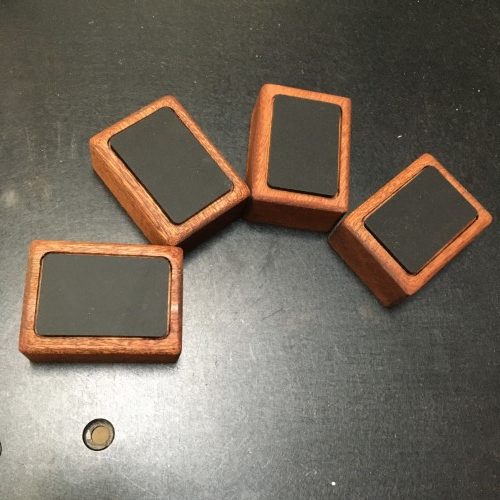

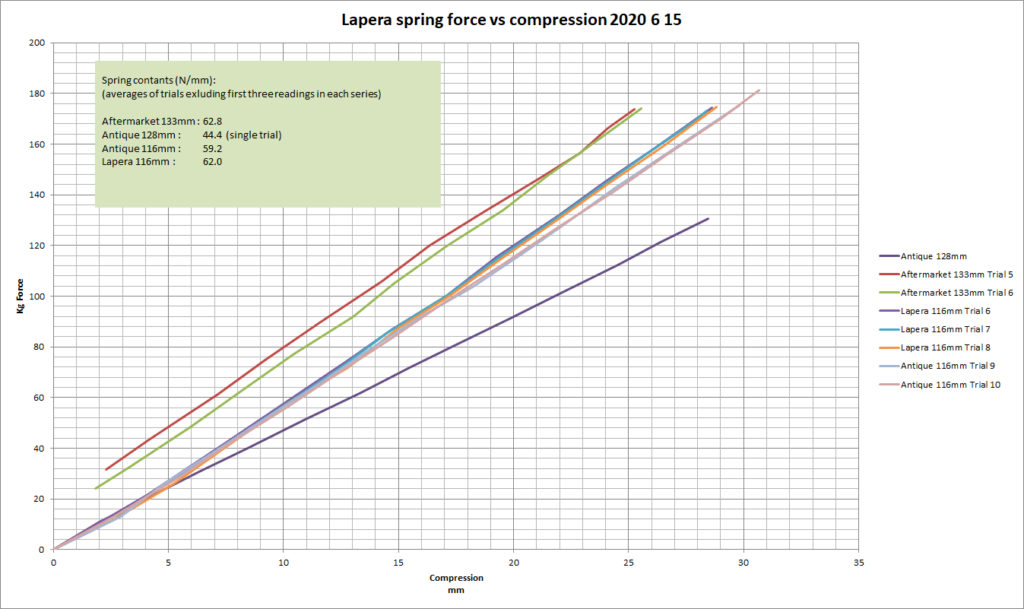

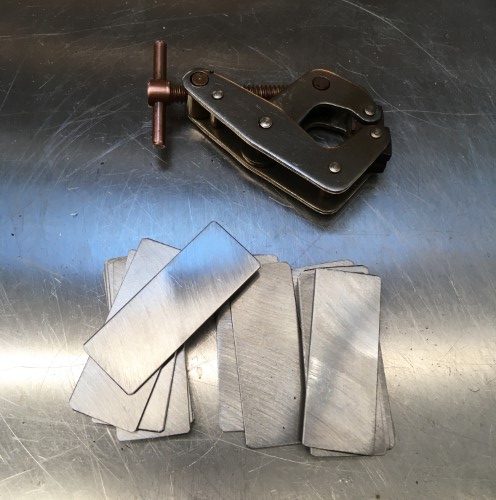

I measured the interior volume of the ‘Papa Bear’ version and compared it with the volume of the vintage HX horseshoe (modeled in CAD): 115ml for the vintage and 135ml for Papa Bear. So I put Papa Bear to the bandsaw, and cut him down to make Mama Bear.

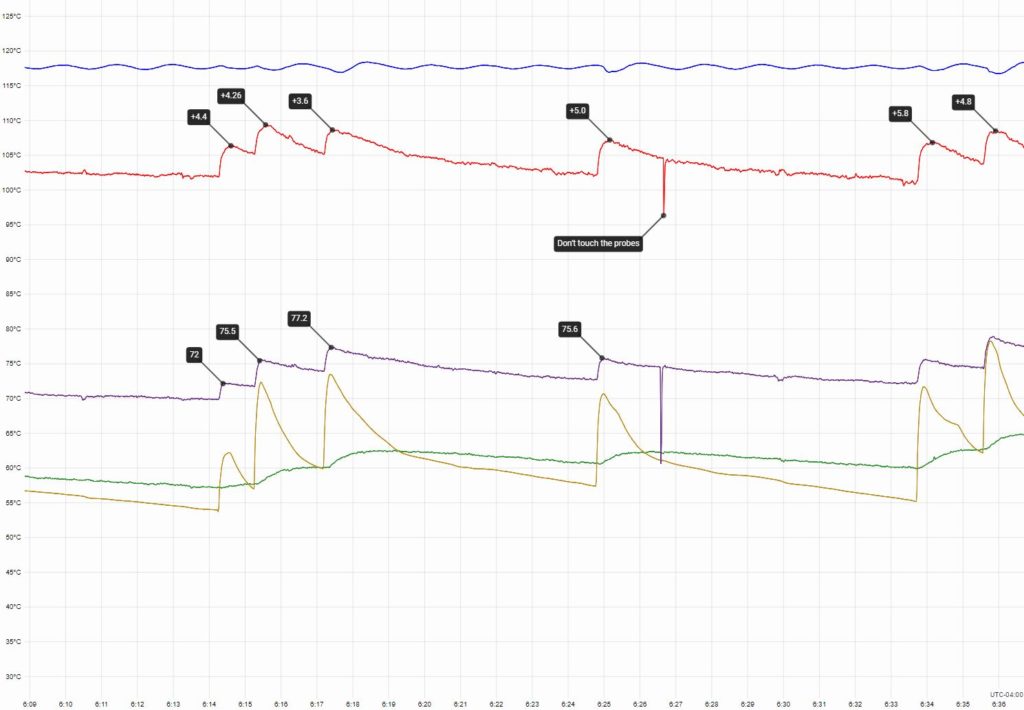

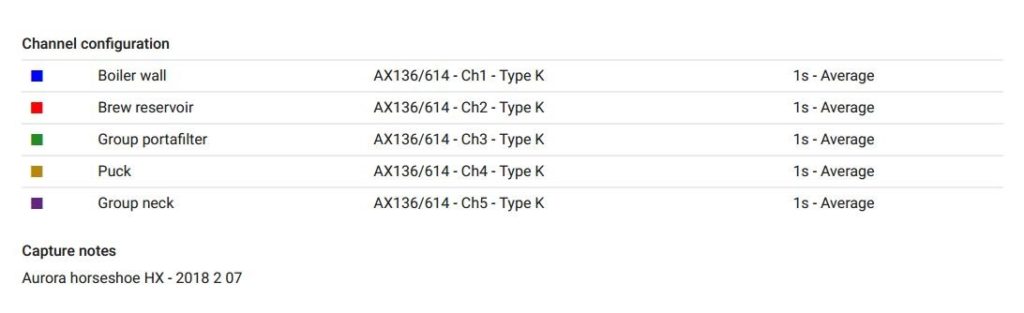

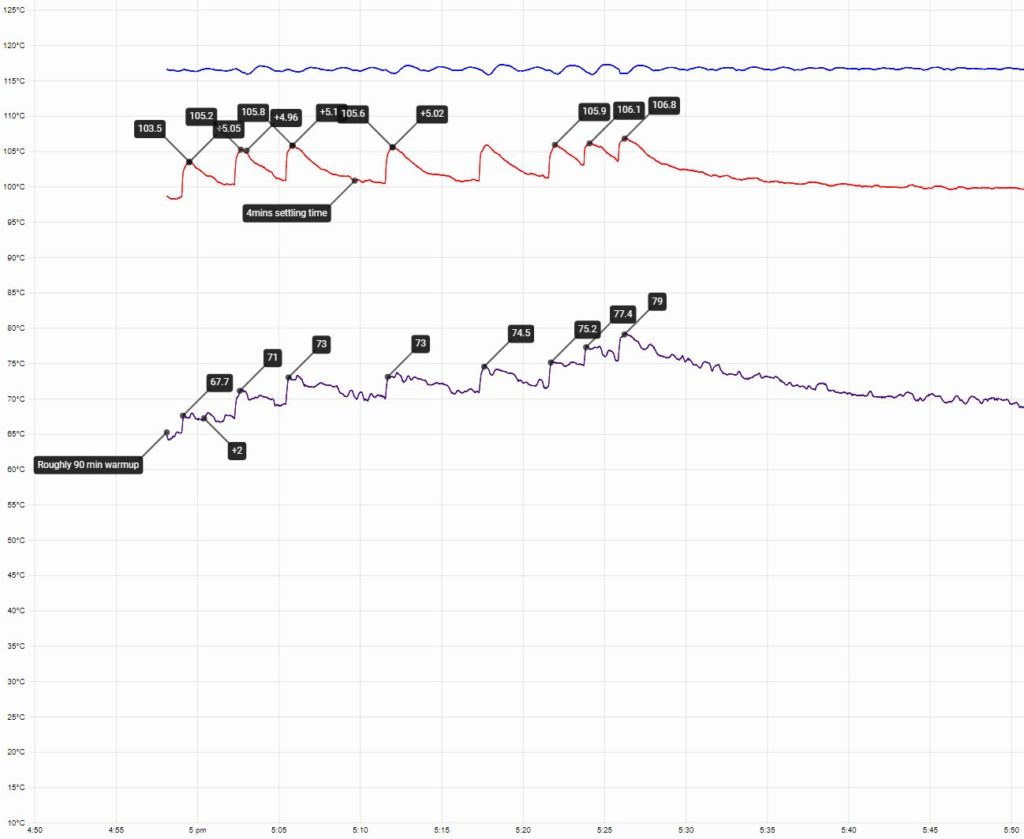

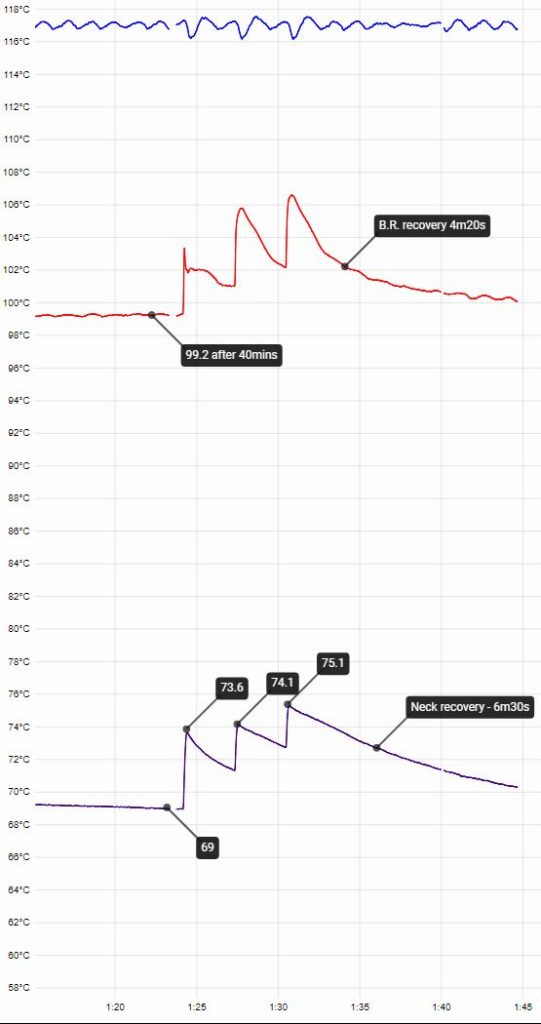

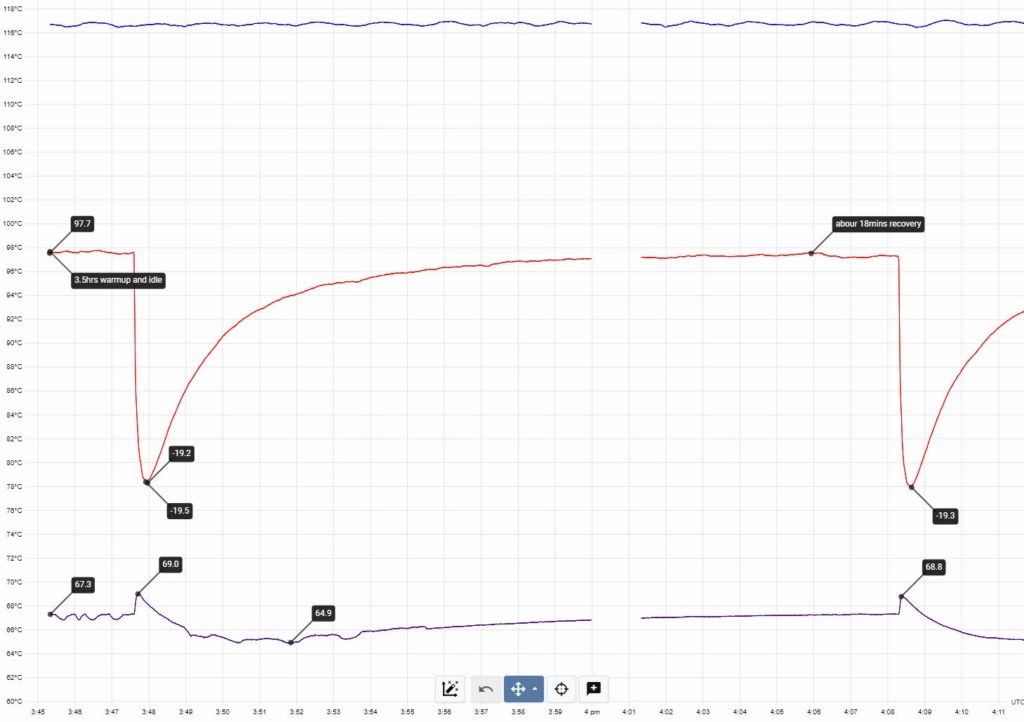

Blue – Boiler

Red – Brew reservoir

Purple – Group neck

(The data for the neck was very noisy for some reason that day – the rapid deviations do not reflect what is actually going on.)

Despite having the same volume as the vintage tube, ‘Mama Bear’ doesn’t behave the same way. The peaks in the brew reservoir temperature are similar to Papa Bear, i.e. around 5 degrees, and recovery times are about the same. It should be noted however, that with adequate recovery time, the neck temperature shows a high degree of stability.

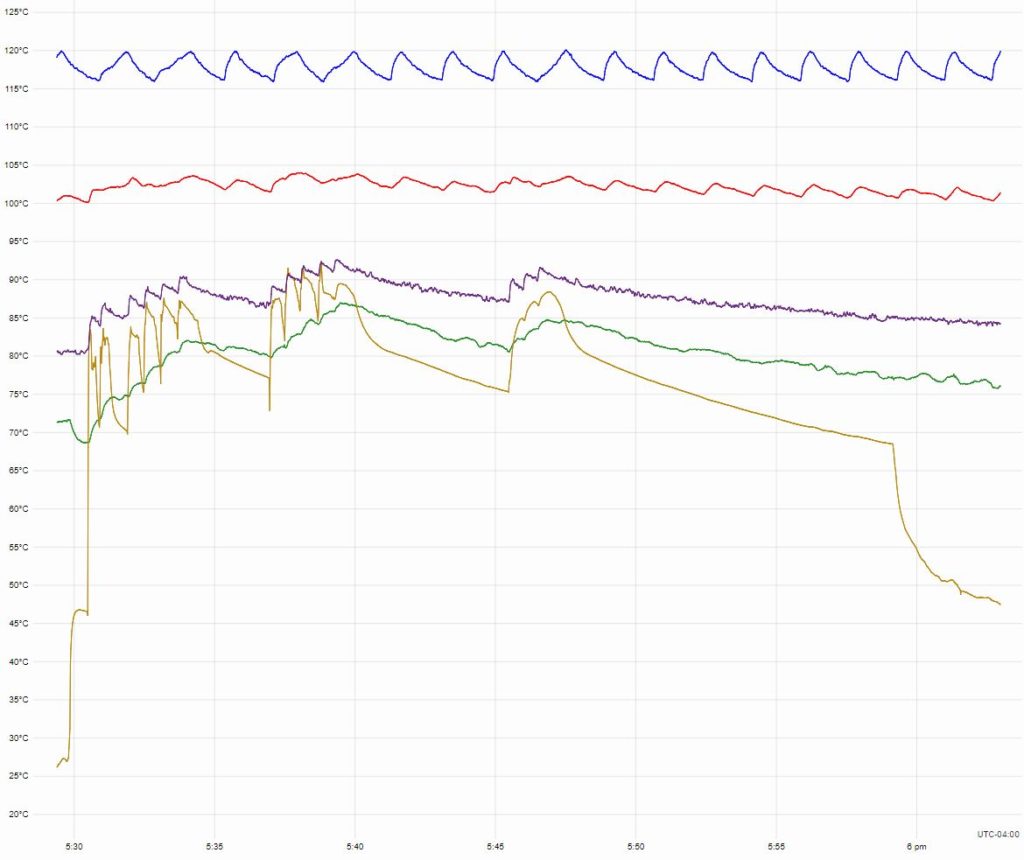

I then modified the horseshoe again, lowering the volume to around 100ml (Auntie Bear??) – but the results didn’t change significantly. So I decided that drastic measures were called for: ‘Baby Bear’ – roughly 60ml volume which is about half of the vintage.

Though the results are better, there are still spikes in the brew reservoir temperature.

Time to alter the Goldilocks plot line.

Introducing ‘No Bear’! Partly to make sure that I wasn’t entirely out to lunch but also to measure the other extreme, I connected the supply to the brew reservoir directly to the mains, bypassing the HX and injecting room temperature water into the reservoir. Unsurprisingly the results are dramatic!

Very cold porridge indeed.

Interestingly however, while the neck temperature rises by a few degrees initially, it recovers quickly (less than a minute) and then drops to 2.5 degrees below idle.

Where does this leave us? The concept of the HX is of course to inject (fresh i.e. non-boiler) cold water through the hot water in the boiler in order to raise it to the ‘correct’ temperature to feed the reservoir. If the machine has been idle for any length of time, the water in the HX will be at the same temperature as the boiler. Subsequent shots will draw cold water into the HX, which, depending on how it is designed, will consistently bring room temperature water up to a specific temperature (either boiler temperature or slightly lower), as long as the heating element can keep up with the demand. So some not very earth-shattering conclusions:

- Changing the design of the HX will determine the temperature ‘profile’ of the water delivered to the brew reservoir.

- Somewhere between 60ml and 0ml of HX volume, the water delivered to the reservoir will offset the heat gain and result in equilibrium.

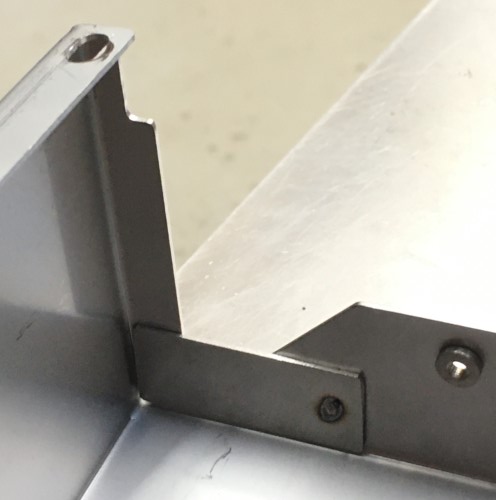

There is one additional question that results from the three bears test: why do identical horseshoes in the vintage and new boilers not exhibit the same thermodynamic behavior? My hypotheses is that materials used for the brew reservoir and boiler are playing a much bigger role than I first thought. Both of these parts on the prototype are made from stainless which is roughly 20 times less thermally conductive than copper and bronze. To test my theory, I put the prototype group onto the vintage machine: compared to the all-stainless boiler assembly, the new group runs around 12 degrees hotter on the copper/bronze boiler. The stainless brew reservoir is slow to acquire heat from the boiler and the water in the reservoir and reluctant to relinquish it to the air or pass it on to the group.

SO…. two rather more significant conclusions:

1 – There should be (or rather, spoiler alert, there is, as will be seen in an upcoming episode) an HX design that meets the requirements of stainless boiler and group combination.

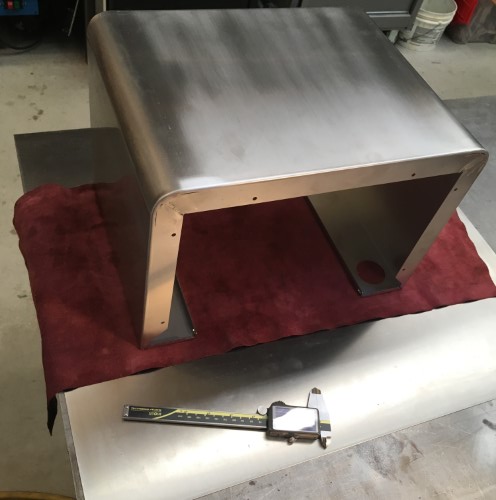

2 – It is time to make a new boiler – using the bronze brew reservoirs that I received a few months ago.