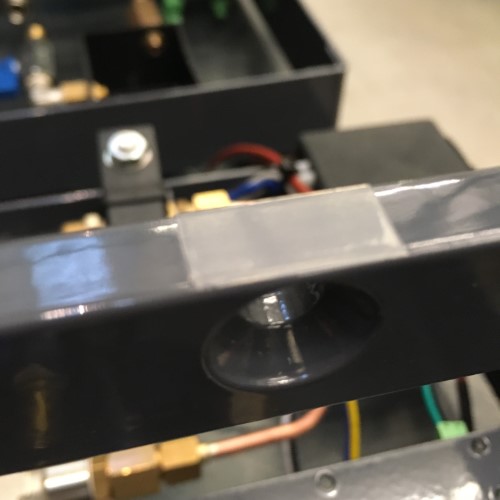

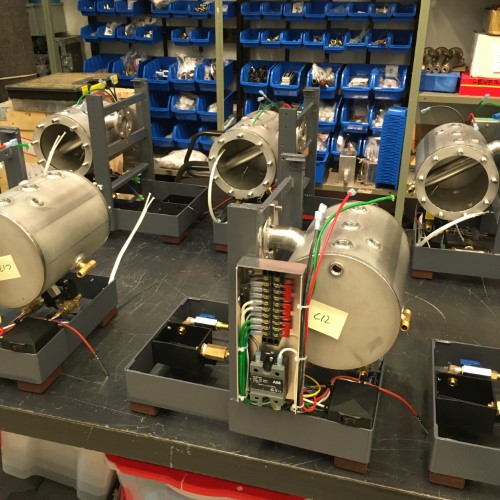

A small but nonetheless significant milestone was past today: the installation of the boilers! This what the assembly area looked like in the morning:

All of the difficult-to-access-once-the-boiler-is-installed parts are in place and it was time to put make the transition from seemingly random collection of wires and hydraulics into something closer to an actual coffee machine. Imagine!

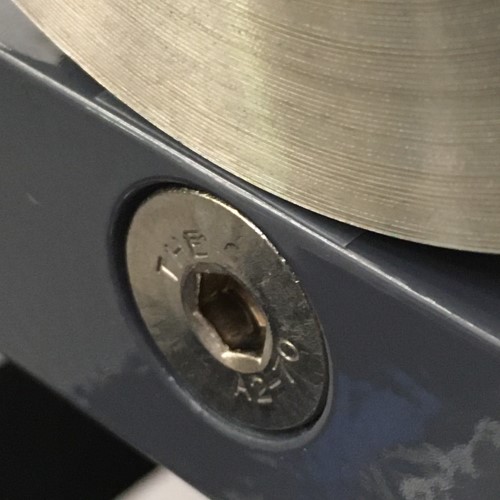

One small detail that isn’t visible to the naked eye is the low-friction cushion tape that prevents the frame from being damaged by the boiler flange.

FOOOOOcus!!

Removing the boiler is not an operation that will happen many times over the lifespan of this machine (at least that is the plan), but preventing damage to the paint at a connection adjacent to a(n at least theoretically) consumable gasket is a good idea…

…details.

Wow, this really look like a production line now. Impressive quality and care level.

Looks very interesting. Will there be a rotary pump or is it assumed that line pressure will feed the HX? Will there be any way for the user to push temperature higher or lower??

The machine is intended to be fully plumbed in; so no pump. As you suggest, line pressure is used for the boiler autofill and to provide pre-infusion pressure for the group via the heat exchanger. The boiler is the only heat source for the entire thermodynamic system. In addition to generating hot water and steam it provides heat for the group and the heat exchanger. Through a careful selection of materials, geometries and volumes, heat gain through conduction is carefully balanced against heat loss through radiation/conduction to achieve ideal and very repeatable temperatures at the puck. The temperature of the group and brew water can be very easily adjusted, albeit indirectly, simply by altering the boiler set point – which can readily be done through the menu system of the controller.

So, the output temperature is flat at the puck?

It would be nice to have a heat exchanger pre-puck to provide a temperature profile.

Hi Jonathan,

That is a difficult question to answer briefly. The temperature of the entire system is controlled indirectly by altering the temperature of the boiler using the PID controller. There is roughly a 26 degree offset between boiler temperature and group temperature. I use the word “roughly” because the question “what is the temperature of the group” sounds simple in theory, but is actually very difficult to answer if one also asks “where” and “when”.

You can read about the development and testing of the heat exchanger in a series of posts that start here.

Best,

Thomas

What gasket material did you go with for your machines? All the old ones seem to have used some sort of graphite fiber gaskets. Now people seem to go with Teflon? Silicone? or another graphite gasket? Does Teflon get to much creep? I saw a copper gasket that looks interesting too. Then thinking about something that’s “food safe”. Confusing to think what to use, curious what you used. :)

Boiler gasket.. :)

Boiler gaskets used to be made from asbestos (!).

These were replaced, for obvious reasons, with “alimentary paper gaskets” – which is some kind of fibre impregnated with some kind of oil or resin – no idea what.

These are ok as far as they go, but require a huge amount of pressure in order to seal against the relatively low pressures in the system, are notoriously leaky and very often the cause of boiler demise.

All the paper gaskets in the machine are replaced with modern glands with o-rings in food-safe high-performance artificial rubber.