So, what’s with the name? Lapera means the pear in Italian. It is a nod, of course, to the origins of these fabulous beasts as well as being the name of my existing design company: Pear.

To inaugurate my new home I decided to do something a little special: a coffee machine needs a name, and the name goes on the badge!

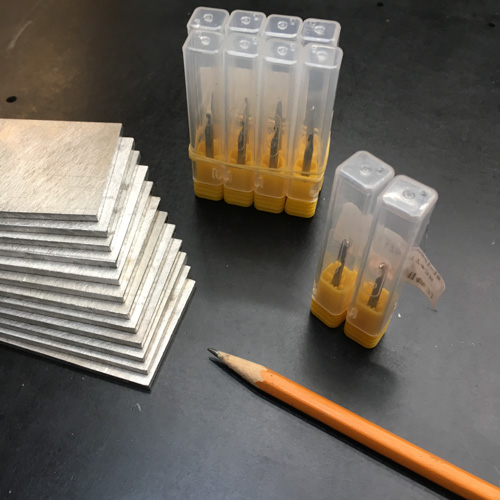

We start with a few iddy-biddy single-flute bits and a stack of aluminum blanks.

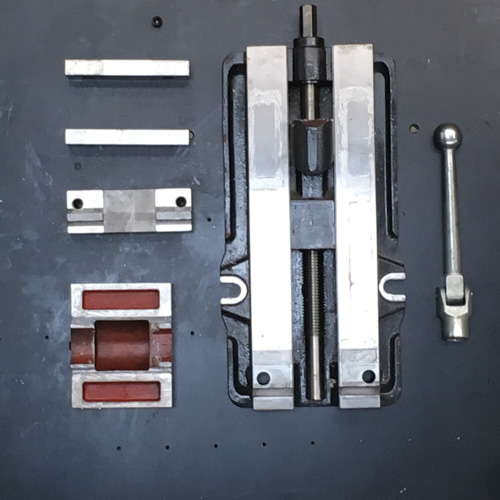

And a clean vise – you have to maintain your vises in order to maintain your vices. I really should be out-sourcing this part because there are more efficient ways to make it, but, for the first batch at least, these are gonna get made in-house.

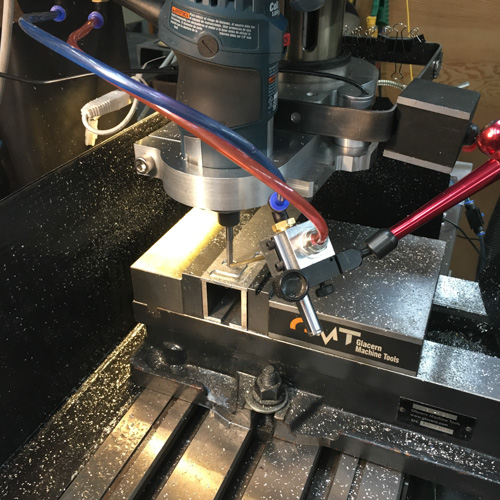

A mist setup on the mill keeps the cutter clear of chips. Which isn’t a big deal for the large bit used for the clearing, but is vital for the smallest one which is less than a 1/16″.

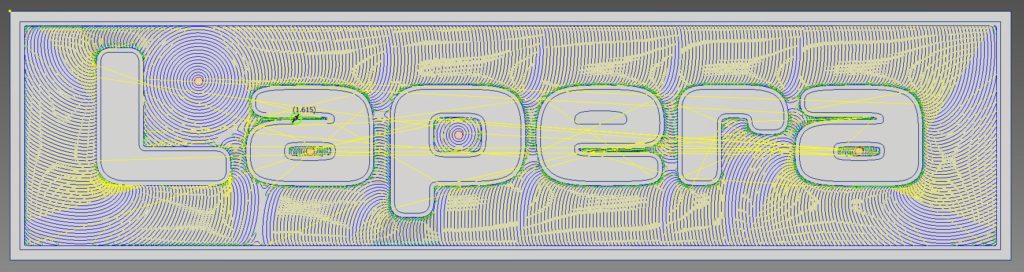

The milling path generated by the CAM software is highly satisfying.

Initial machining is done.

Lots and lots of cleaning comes next: rinsing, ultrasonic de-greasing, chemical etch, more rinsing, baking to bring any residual oils to the surface, solvent bath and yet more rinsing.

I borrowed these guns from a friend who “doesn’t miss powder coating”. I completely agree – this process is a hassle to do for large or numerous parts unless you have a really good setup and do it all the time. The guns are fascinating, for a number of reasons, not least of which being that they are the first and only ‘product’ that I have used that is almost entirely manufactured with a plain-old PLA 3D printer.

The powder coat itself looks like pretty dull stuff.

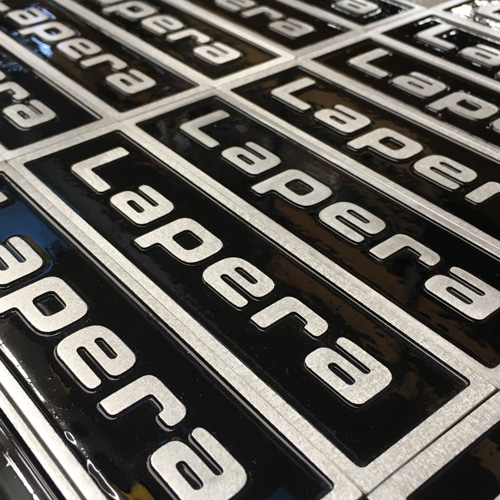

But it sure shines up nice after a quick trip through the oven.

After a quick sanding to reveal the bare metal, a little bit of a trim and a clear coat, the badges are ready to join the fleet.