So, what’s with the name? Lapera means the pear in Italian. It is a nod, of course, to the origins of these fabulous beasts as well as being the name of my existing design company: Pear.

To inaugurate my new home I decided to do something a little special: a coffee machine needs a name, and the name goes on the badge!

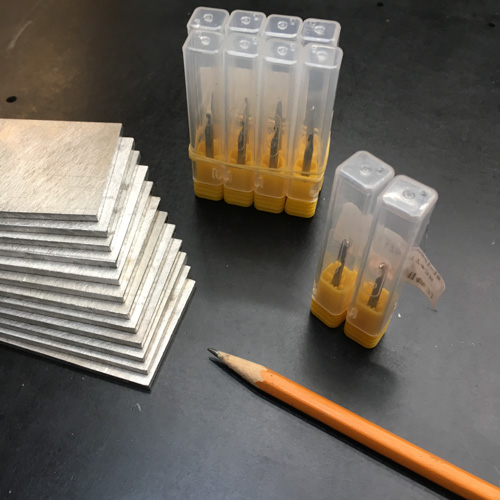

We start with a few iddy-biddy single-flute bits and a stack of aluminum blanks.

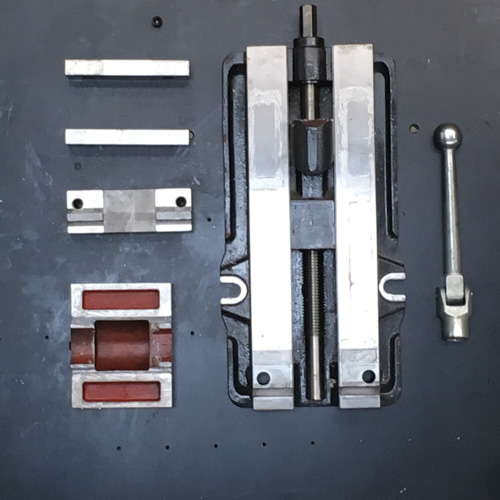

And a clean vise – you have to maintain your vises in order to maintain your vices. I really should be out-sourcing this part because there are more efficient ways to make it, but, for the first batch at least, these are gonna get made in-house.

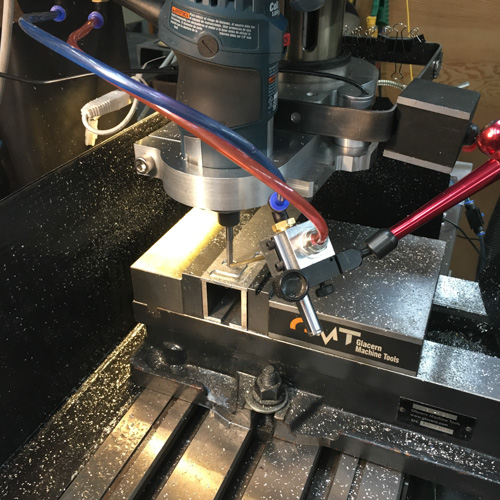

A mist setup on the mill keeps the cutter clear of chips. Which isn’t a big deal for the large bit used for the clearing, but is vital for the smallest one which is less than a 1/16″.

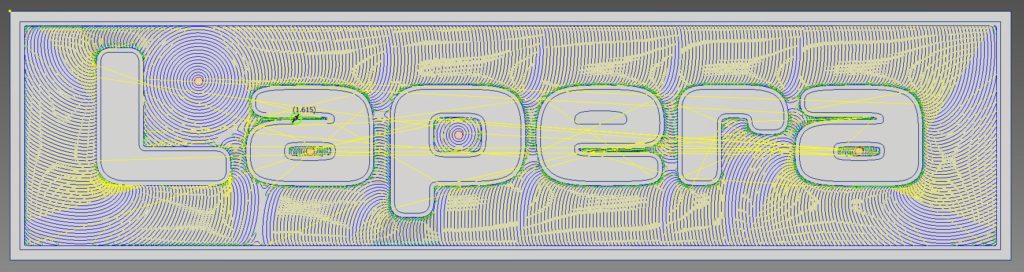

The milling path generated by the CAM software is highly satisfying.

Initial machining is done.

Lots and lots of cleaning comes next: rinsing, ultrasonic de-greasing, chemical etch, more rinsing, baking to bring any residual oils to the surface, solvent bath and yet more rinsing.

I borrowed these guns from a friend who “doesn’t miss powder coating”. I completely agree – this process is a hassle to do for large or numerous parts unless you have a really good setup and do it all the time. The guns are fascinating, for a number of reasons, not least of which being that they are the first and only ‘product’ that I have used that is almost entirely manufactured with a plain-old PLA 3D printer.

The powder coat itself looks like pretty dull stuff.

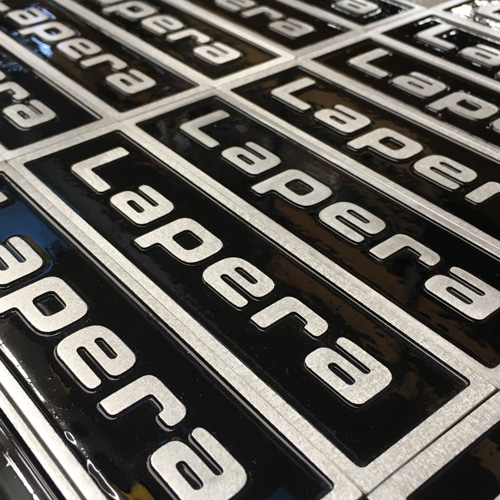

But it sure shines up nice after a quick trip through the oven.

After a quick sanding to reveal the bare metal, a little bit of a trim and a clear coat, the badges are ready to join the fleet.

Hi Thomas,

I have heard that Ascaso no longer carries Aurora group springs…(and Ascaso springs were plated steel.)

Will Lapera have a stainless spring?

Cheers,

Paolo

Hi Paulo,

Yes, the Aurora group spring is no longer available at Ascaso – or anywhere else that I know of. I haven’t decided yet what material is going to be used for the Lapera group. Stainless is well, stainless, but it may or may not have the right material properties for this exact geometry and application. Regular spring steel, properly coated with some kind of corrosion inhibitor is adequate for the task as long as the proper maintenance is done (which, as we all know, is always the case :).

I am just curious if you’ve made these decisions yet about the group and spring material?

The design of the group is complete and I am expecting one last part from a manufacturer in a week or so. I will be writing a post about the design and the material selections soon. So no spoilers here :)

Hi,

I’m reaching out because I’m overhauling two Aurora-Burgnetti machines in The Netherlands. Recently visited Henk Langkemper, who claims to own your nr 1 machine ;)

I would really like to contact you regaring the springs in your group. I’ve tried to source them, or even have them hand-made, but there seems to be no perfect solution to the compressed spring size and the 44N/mm springrate. Hopefully you understand my urge to rebuild these two wonderful Aurora-Brugnetti two-group levers, but I want to do it right. Right?!

I deeply respect your work!

Pee Groothuizen

Hi,

No problem, the Lapera spring will fit the Aurora group. You are correct in that the old design(s) is/are problematic – I’ve never seen two the same…

I’ll contact you directly.

Best,

Thomas