What is new for the 3rd edition?

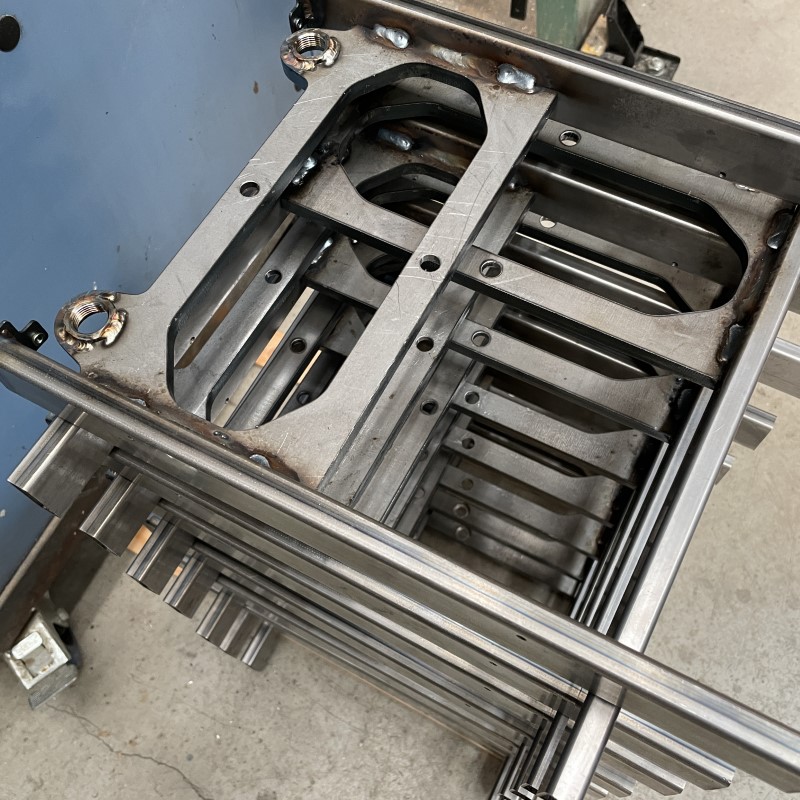

The group is getting a few modifications. The original design comprised two castings: the main body and a short sleeve, that were thermally shrink-fit together and machined after assembly.

We have replaced the second casting with an AISI 316 sleeve that lines the entire bore of the body. As well as being easier to manufacture and thermally indistinguishable from the all-bronze version, the sleeve has benefits for water distribution. First, it is compatible with E61 slip-on shower screens; we now use a 35µm mesh screen which we found gives the best results after considerable testing. Second, a radial channel around the outside of the sleeve distributes incoming brew water and injects it into the brew chamber via 8 ports instead of the single port in the original design.

These two changes improve the symmetry of the water flow into the chamber and result in a reduction in turbulence above the puck. We have also moved away from bronze to stainless for the cam for strength and longevity and to reduce our use of chrome – which we do wherever possible for environmental reasons.

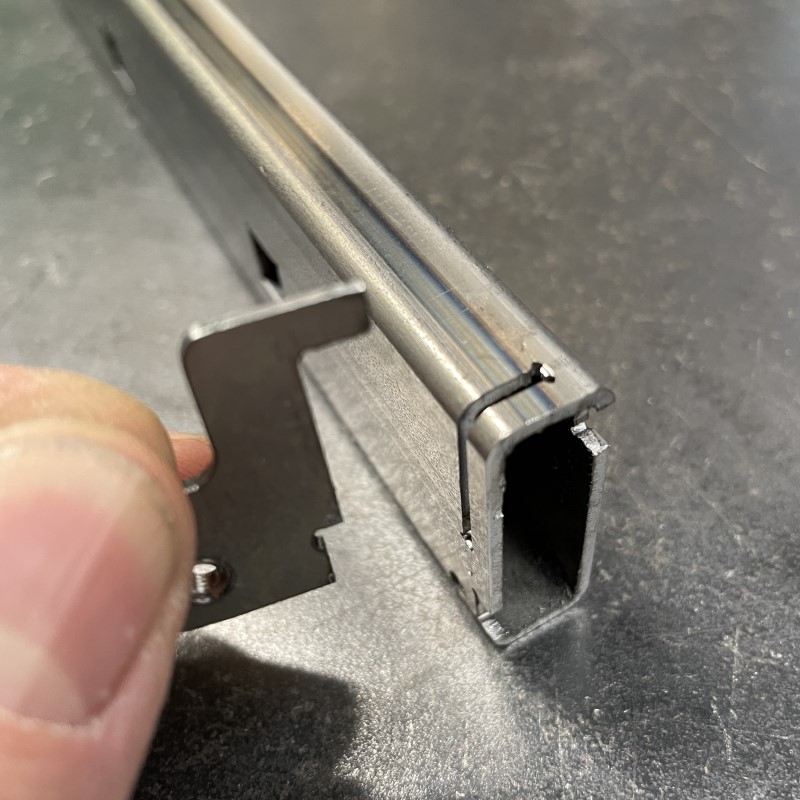

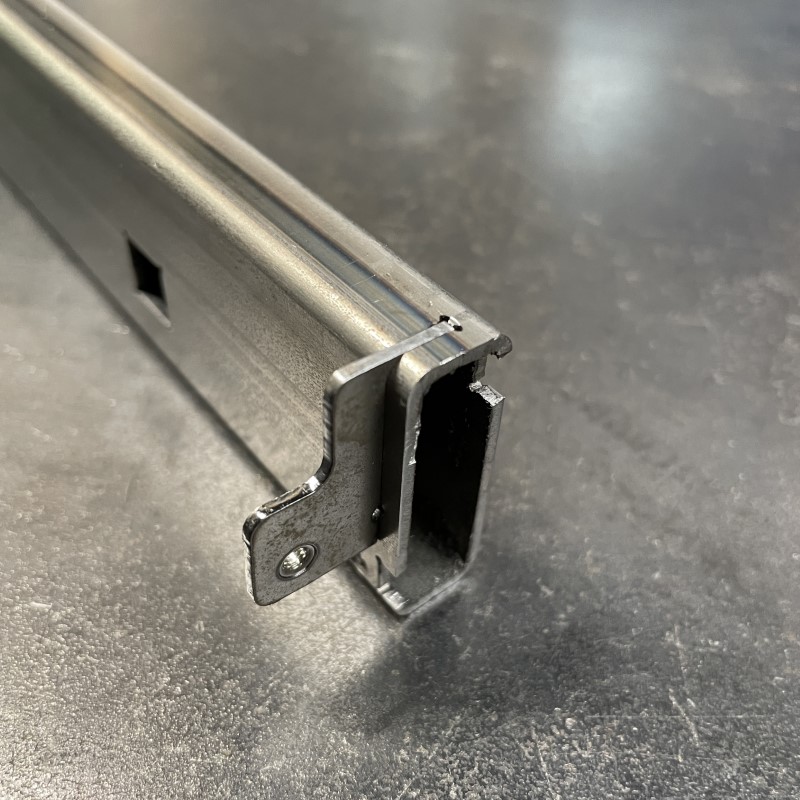

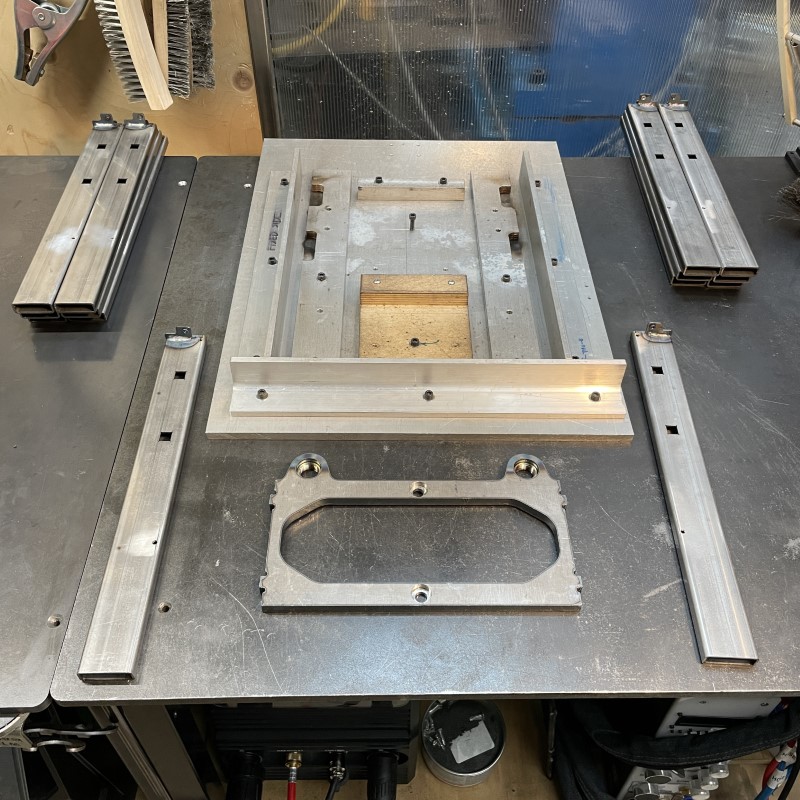

The other changes, with a few exceptions, are incremental improvements that either simplify or improve the stuff under the hood. This is done not just to streamline the manufacturing and assembly process, but to build a more robust machine – in short: the simpler it is, the less there is to go wrong. Changes like this include a redesigned boiler that makes welding (slightly) easier, a new, stiffer, laser-cut 3D jigsaw puzzle frame, a reworked hydraulic system to reduce component count and to make assembly and maintenance easier, some streamlining of the wiring harness and the elimination of a couple of internal plastic parts.

I mentioned that there were a few exceptions to the incremental-type improvements. The first, which is still in development but will should make it into this edition, is a new interface for the electronics. The interface in the first two editions – a very small screen with three control buttons – was located under the cup warmer to protect it from water. A new (slightly larger) screen and capacitive touch interface are being integrated into the splash-proof main electronics housing under the drip tray.

A new PID algorithm, developed and optimized specifically for the DS by an expert in renewable energy systems with a PhD in electrical engineering, brings an entire order of magnitude improvement in boiler temperature stability. What difference does this make to the expresso? None that I can tell as the thermal stability of the massive bronze group casting smoothed out what little variation there was due to the previous algorithm. But ten times better performance is still ten times better – how can you say no? Oh, and I nearly forgot that we now also have a formed drip tray insert that radically diminishes standing water – no more puddles.

And there are also the coffee tools of course, DS owners get an automatic 15% reduction on all the Lapera tools and we will powder-coat them to match any custom colors.