August is very fine. People take holidays. In France and other places in Europe where the sun shines more than occasionally, things start slowing down in July and people “faire le pont” until sometime in late September when they finally remember they had a job. Trying to do anything other than sitting by the pool and taking four hours for lunch (i.e. an hour longer than usual) in August in Italy just isn’t worth attempting. Here in Montreal we are more organized; we like to do things together: along with Moving Day, July 1st, when everyone moves at the same time (Which is insane. Try to find moving truck on that day. I’m not making this up.) we also, as anyone who lives here can attest, tear up all of our roads and rebuild all our overpasses and bridges at the same time. It is more efficient to wait fifty years and then get it all done in one go, ripping-off-the-band-aid-style. Economies of scale you know. We also have this thing called the The Construction Holiday. Towards the end of July, once we are done ripping up the asphalt and putting out the traffic cones, we all go on our government mandated holiday for exactly two weeks. On the same day. We also all come home at the same time. Over the interchanges that we are rebuilding and along the roads we tore up before we all went on holiday. Sensible I call it.

Welding the boiler together is a complicated set of procedures. Each type of weld requires a different setup and either a judicious application of inert welding gas, a custom heat-sink or both. Some operations render others either difficult, or in some cases impossible, so it is critical to get the assembly order right. To further complicate matters, each weld introduces some distortion in the parts: more or less depending on their geometry and the amount of heat that goes into the weld.

The HX tubes are easy. The size and fit of the parts makes for a simple weld that is almost invisible.

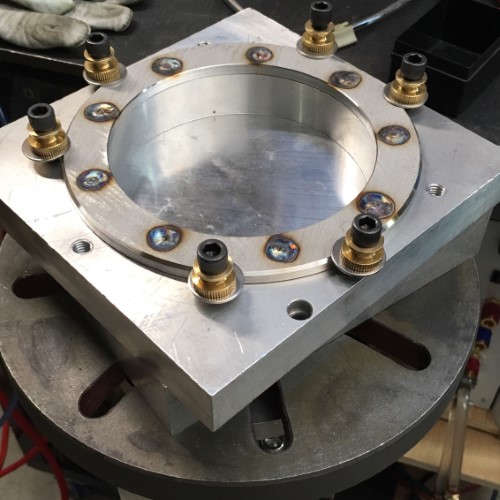

Ditto (once the heat-sink is made) for the bolt ring.

Just load your nine-shooter and fire away!

All the bolt rings were welded up in about an hour.

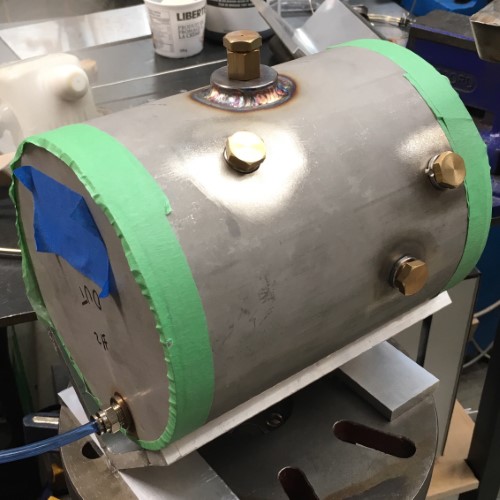

Fitting the HX tube in place requires a more complicated setup as both the inside of the boiler and the HX tube have to be purged with inert gas during the weld.

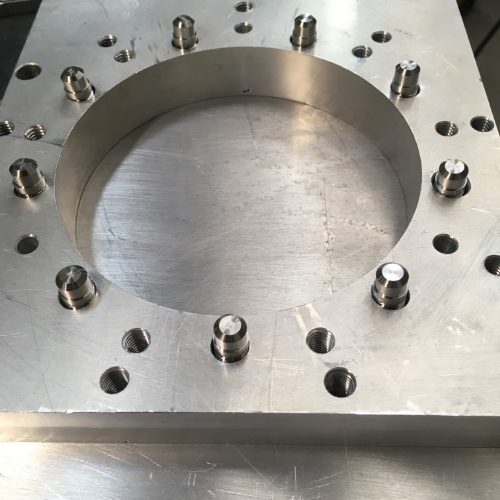

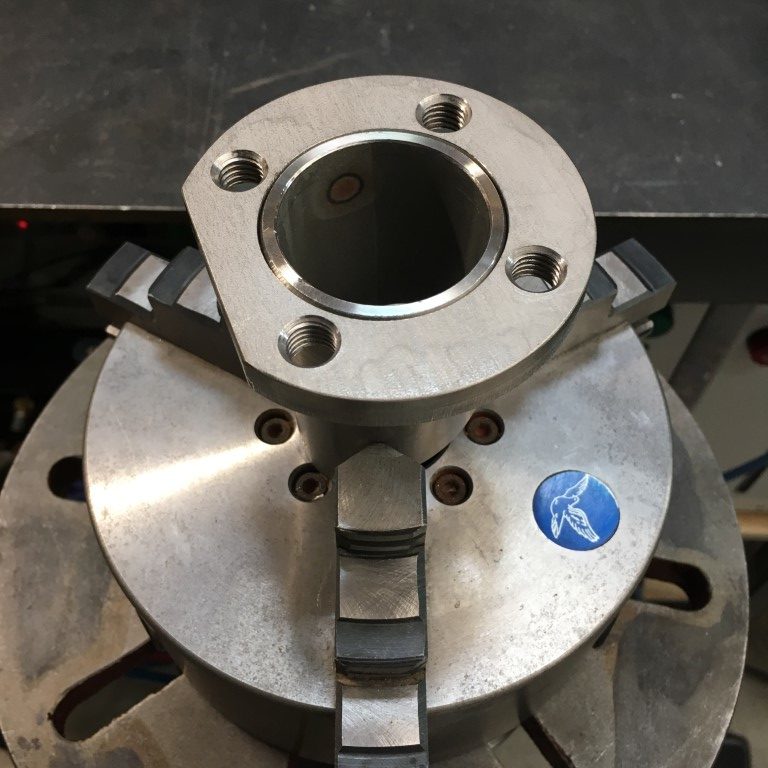

The group mounting flange and brew reservoir meet for the first time.

The end flanges are also done using the turntable (a.k.a. the Ouroboros machine).

A few welds later and after some clean-up: the first full-stainless diagonal heat-exchange boiler off the production line.

This one is now ready for a few tests before the rest are assembled. Mistakes at this point would be, ermm, disappointing.

.

.

.

.

1 – MONTREAL, QUE.: AUGUST 21, 2014 — Construction cones line Rene Levesque Blvd east of Atwater Street in Montreal, on Thursday, August 21, 2014. (Dave Sidaway / THE GAZETTE) Web 4×3 ORG XMIT: POS1410031753473482

Hi Thomas,

It is exciting seeing your Lapera coming together on your Instagram pages.

https://www.instagram.com/laperacoffeemachines/

Can you please tell me what materials you are using for the frame and for the case of the Lapera?

Cheers,

Paolo