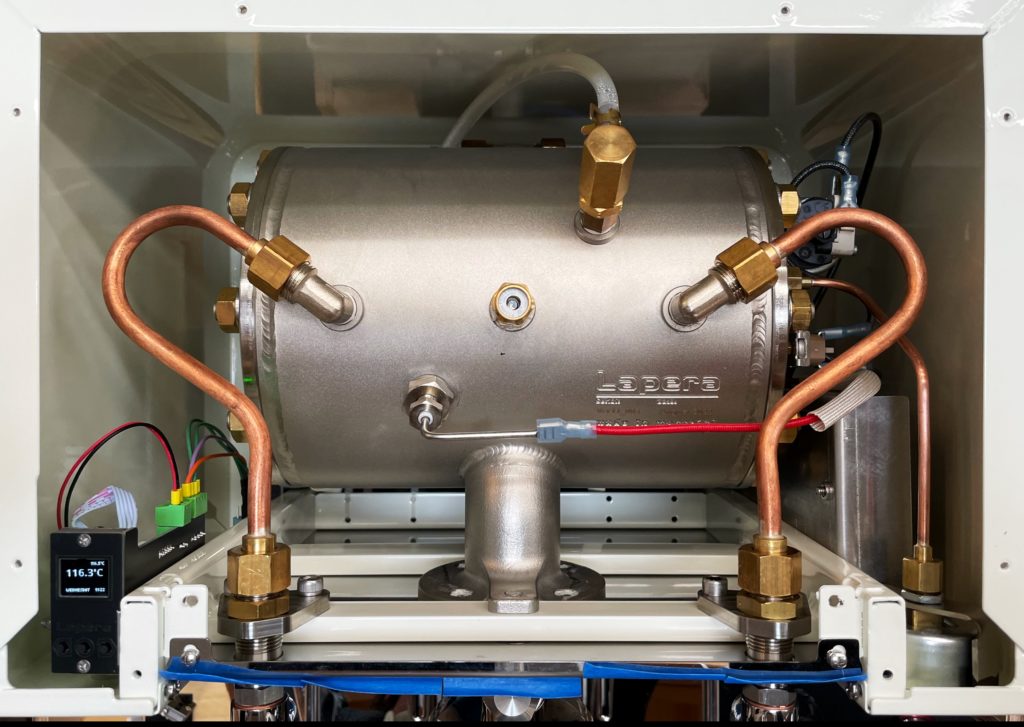

The 2nd edition Lapera DS hydraulics look, at first glance, a lot like the first edition. BUT they are not!

- Here is what’s new in the redesigned boiler and hydraulic system:

- All boiler components are 316L stainless steel and are welded by The sTIG®

- Double-flanged boiler opens at both ends for cleaning

- Engineered o-ring gland seals on the main boiler openings and the group (which seal to higher pressure at significantly lowers levels of torque) – trust me they are just better

- Monolithic cast-stainless heat exchanger brew reservoir

- New layout of upper and lower pipe runs for ease of installation and service

- New slimmer over-pressure safety valve

- New (La Marzocco) anti-vacuum/burp valve and silicon tubing (with an heat-shedding extension to prolong the life of the otherwise slightly fickle o-ring in LM’s design) – no more steam and condensation in the boiler compartment during warm up

- Redesigned end flange incorporates a dedicated rigid connection for the safety pressurestat

- Redesigned breakout circuit board with upgraded connectors to facilitate assembly and maintenance (this has nothing whatsoever to do with the hydraulics, but it is new and in this photo… so)

A quick word on the pressurestat, which I perhaps haven’t discussed elsewhere:

The p-stat is primarily a safety feature as the machine is electronically piloted by the Lapera controller using PID. In its current configuration, it serves to cut electricity to the entire system in the (unlikely) event of runaway heating and overpressure (in which case it will also deploy oxygen masks to all passengers). Under normal circumstances it will never operate. However, electronics are inherently more complicated than everything else here and are therefore, by definition, orders of magnitude more prone to failure. To address this issue, we have taken a “black-box” approach to the control and interface design of the Lapera DS: the control electronics are all gathered together in a single, literal black box and the user interface itself is unobtrusively tucked away out of sight inside the bodywork. In thirty years when, say, a power supply capacitor reaches the end of its life, what will happen? In most machines made today, finding spare parts to replace the electronics that are likely integrated into the user-facing interface of the machine three decades from now will be challenging, if not completely impossible. With the DS, simply by changing two wires inside the machine to put the p-stat in line with the heating element you can have a fully-functional machine again while you wait for your ten-year-old to build you a replacement for the black box control electronics.

Please note however, that while batteries are included with the DS, ten-year-olds are not – that part is on you.