I have, over the past few years, spent a surprisingly large amount of time pondering the relationship between boiler temperature and group temperature – which determines the temperature of the brew water. Exciting as my life may sound, this does seem to be something worth thinking about (to me at least). Especially as it turns out to be a fairly complex and therefore interesting relationship to characterize. The Lapera DS is a single boiler with heat-exchanger design, therefore the temperature of the group is controlled indirectly by altering the boiler setpoint (i.e. changing the temperature of the boiler). After a reasonable amount of boffinating, we have come up with a method for thermally profiling the machine. This is specific to the Lapera DS and contains some specific recommendations for Lapera owners, but I think it has some relevance to the thermal behavior of lever machines in general. The findings are summarized in the summary, (that’s what summaries are for after all), but there’s also a bunch of potential semi-contentious and therefore titillating opinions in the conclusion that are worth reading even if you skip all the nice graphs and sciencey bits in the middle.

Summary

This document contains a description of the methodology used to characterize the temperature profile and the relationship between boiler temperature and brew temperature of a Lapera DS lever espresso machine. The results show that brew temperature correlates strongly with boiler temperature and exhibits a decline of roughly 4°C over a 40 second shot (including a 10 second pre-infusion).

Introduction

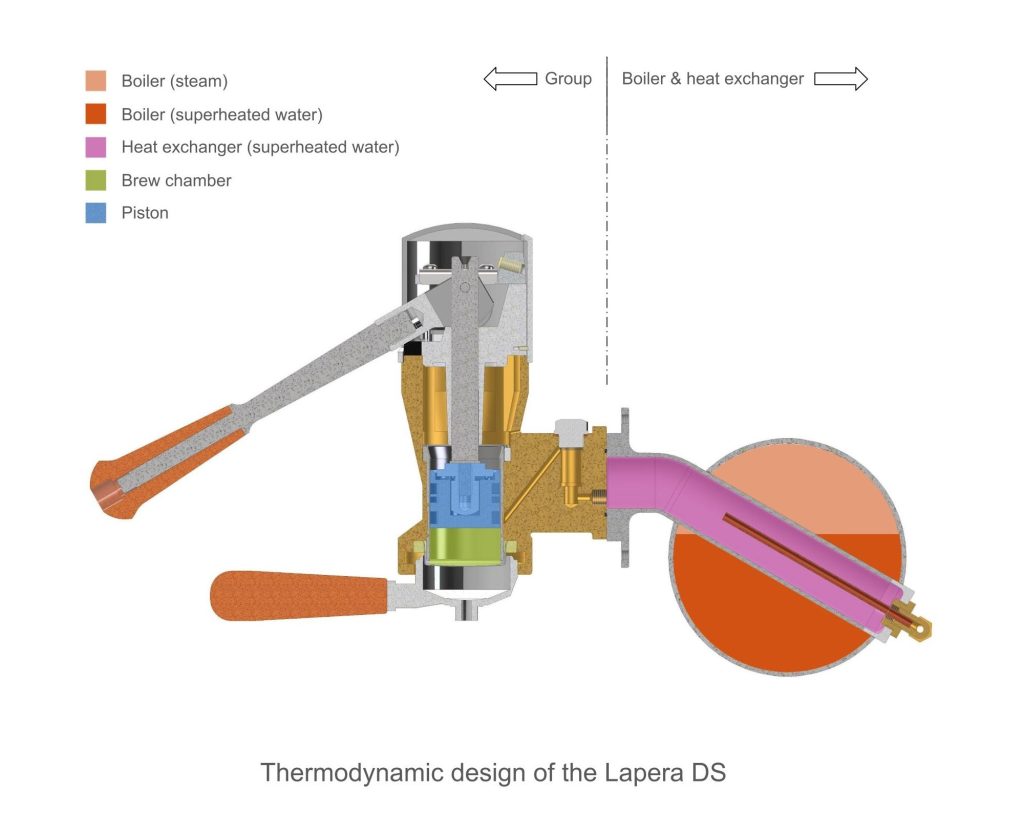

The Lapera DS consists of a single superheated boiler with an external spring lever group that is supplied with water and heat from a heat exchanger that passes through the boiler. The boiler temperature is controlled by a PID algorithm with input from a thermocouple housed in a thermowell inside the boiler. The lever group is physically attached to the heat exchanger and is heated by conduction. During a brew or extraction cycle, water at close to ambient temperature is mixed with the superheated water in the heat exchanger before passing through the internal channels inside the group to the brew chamber.

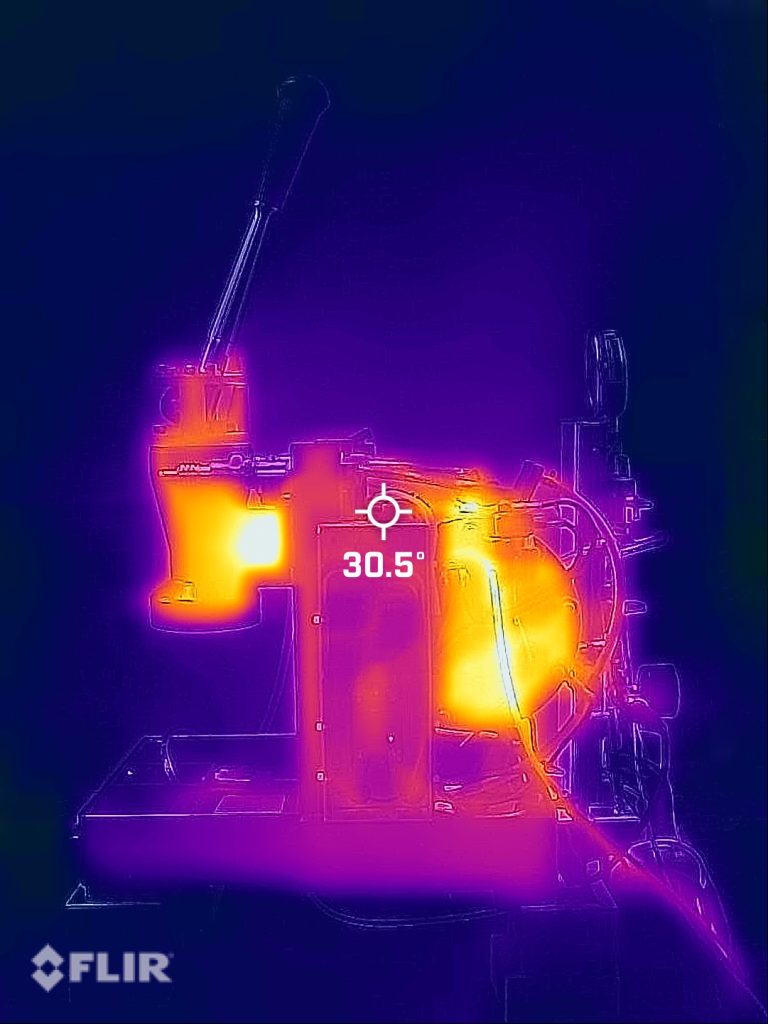

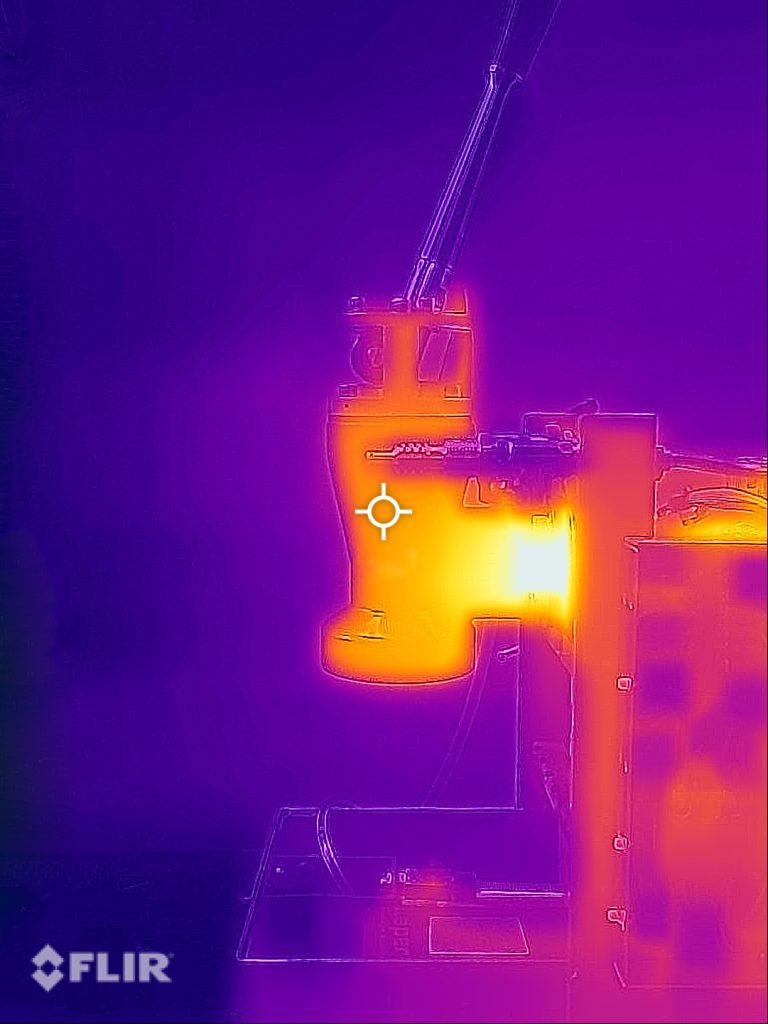

The group, which has a large thermodynamic mass, reaches a thermal equilibrium between the boiler temperature (from 118-130°C) and the ambient temperature of the surrounding environment (20-25°C). The temperature of the group is not uniform, rather it is graduated from hottest, at the point closest to the heat exchanger, to coolest, at the point on the external surface furthest away from the source of heat. At a boiler temperature of 120°C, the temperature of this extremity was measured at 53°C. Thus the channels through which the brew water passes and the brew chamber itself lie somewhere on this thermal gradient. Though difficult to quantify, the average temperature of the group is considerably lower than the generally accepted typical brew temperature of 93°C for espresso. Consequently, the group will draw away some heat from the brew water as it enters the brew chamber. The purpose of this document is to characterize the thermal behavior of the group, i.e. to determine its “thermal signature”, and to measure the offset between boiler temperature and brew temperature “at the puck”, i.e. the temperature of the water that reaches the top surface of the coffee puck during an extraction cycle.

Thermal camera image of the Lapera Group showing a thermal gradient on the exterior surfaces

Definitions and abbreviations:

- Pull – The action of pulling a shot of espresso or simulating the same using a Scace-type device on a spring lever coffee machine.

- Scace-type device – instrument used to simulate and measure an espresso Pull.

- Puck temperature – Temperature measured by the Scace device at the puck.

- Measured boiler temperature – Temperature measured in the boiler from the uncalibrated built-in sensor.

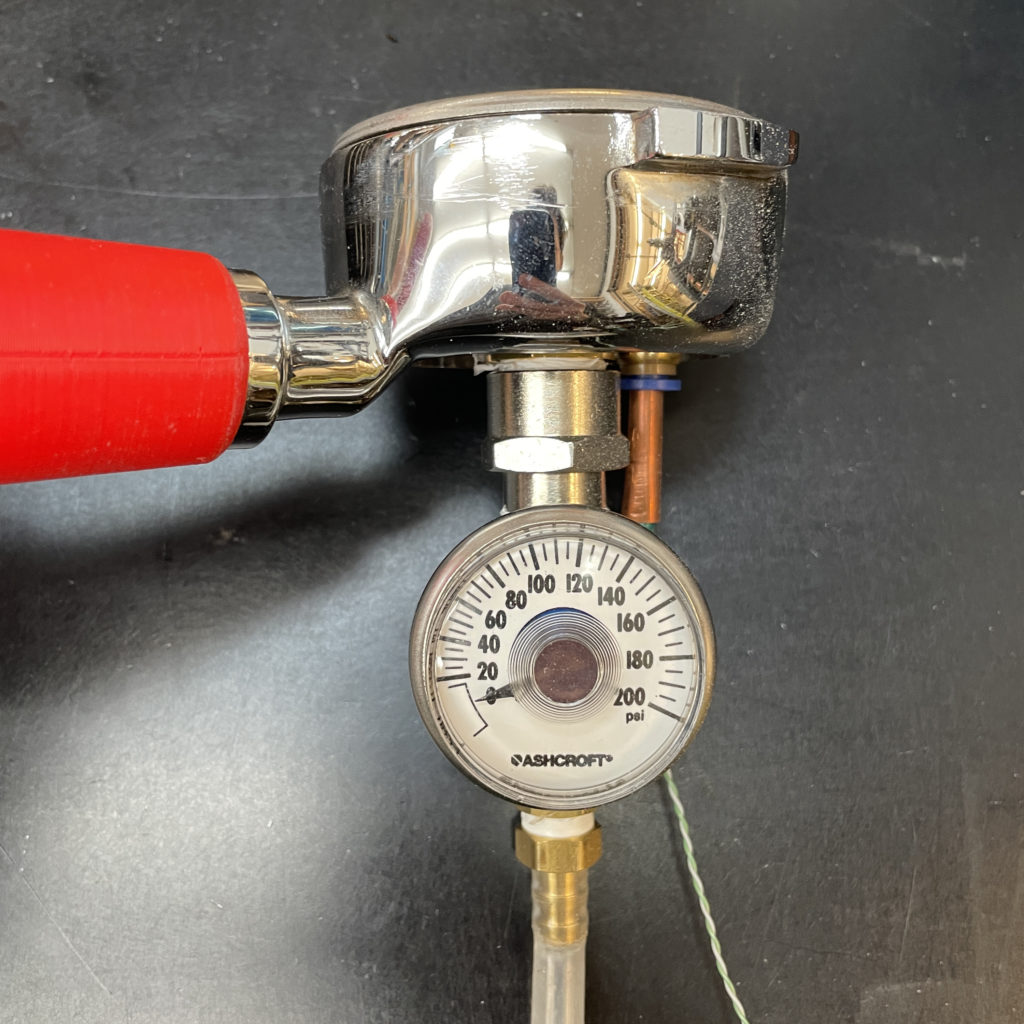

- Boiler pressure – Steam pressure in the boiler measured with a calibrated pressure gauge.

- Actual boiler temperature / Boiler temperature – Boiler temperature calculated from calibrated steam pressure measurements according to the steam pressure table.

- Setpoint – Temperature that the boiler control system aims to reach.

- Puck Peak – Peak temperature measured at the puck

- Puck Average (time) – Average temperature at the puck for a given amount of time.

- Moving Average – Constantly updated average to smooth noisy data.

Equipment used:

- Scace thermofilter-type device

- Picolog TC-08 temperature data-logging hardware and software

- Timer (1 second resolution)

- Scale (0-2000g x 0.1g resolution)

- Amprobe multimeter with k-type thermocouple (1°C resolution)

- Lapera DS3 (3rd edition) lever espresso machine

- KafaTek Monolith grinder

Methodology

Design of the Scace-type device

A good Scace-type device should aim to mimic the thermodynamic and the fluid dynamic behavior of a coffee puck during a standard espresso extraction. The Scace device allows for instrumentation of the extraction process and provides a reproducible Pull by removing the variability of puck grind and preparation. The Scace device used in this experiment is designed to mimic a 20 gram dose of ground coffee in a double basket with a 46 gram extraction volume in under 40 seconds of extraction.

The Scace device is equipped with a temperature probe: a bare type K thermocouple with minimal thermal inertia. Minimizing probe thermal inertia is key to obtaining accurate results in a rapidly changing thermal environment. A probe with large thermal inertia will cause the readings to lag behind actual temperatures and may absorb enough heat to affect the process and distort the corresponding readings. Similarly, the device must have a sampling rate high enough to record any transient peaks.

The fluid dynamics of a bed of compressed coffee grounds is simulated using a 0.1mm calibrated orifice. We have determined via theoretical calculation that 0.1mm orifice will closely replicate a standard Pull. The performance of the orifice was found to closely resemble a properly dialed-in 20g in / 46g out espresso Pull on a Lapera DS3 lever machine in terms of overall shot time and volume (including preinfusion and residual moisture in the puck).

In order to maximize volumetric and thermal consistency, a surrogate puck was machined from low conductivity plastic to simulate the dimensions of a 20g puck of coffee and to approximate its thermal mass.

Data acquisition

The Scace device was used with a data logger to record temperature during a series of Pulls at various boiler Setpoints on a Lapera DS3.

Protocol:

- Machine at idle for at least 1 hour before the start of the experiment

- Recovery time 2 minutes between Pulls

- Preinfusion of 10 seconds

- Machine idle for at least 40 minutes following boiler Setpoint adjustment.

- 6 shots pulled per Setpoint

- Sampling rate 0.2 seconds

- Moving average of 10 samples (2 seconds)

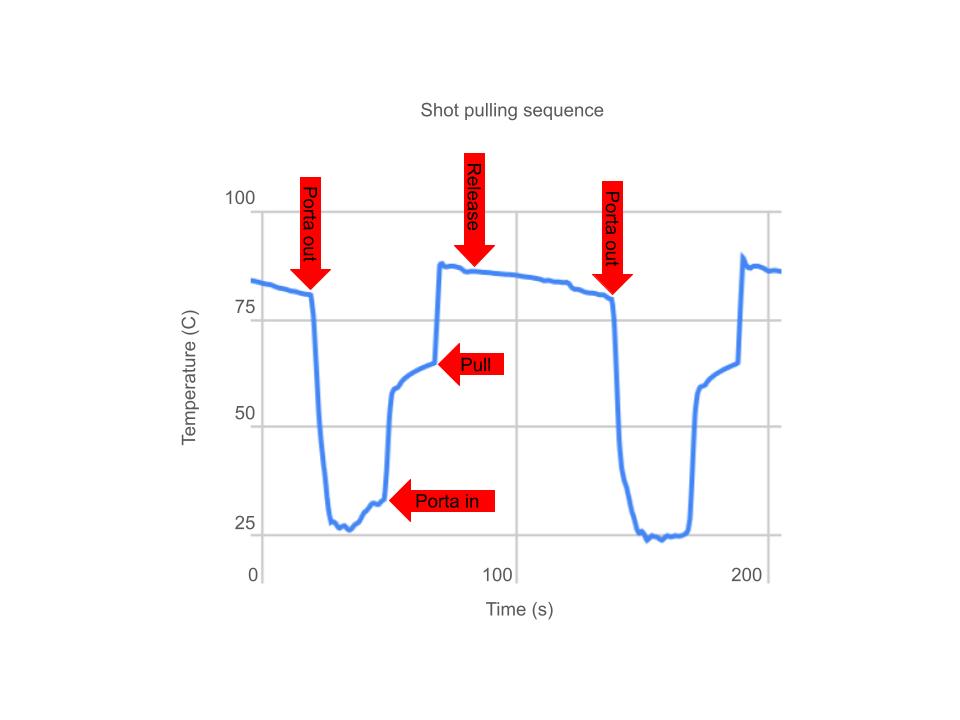

Shot Pulling sequence:

- Portafilter removed from group (30 seconds)

- Portafilter replaced in the group (20 seconds)

- Lever pulled

- Preinfusion (10 seconds)

- Lever released

- Portafilter removed

- Total shot time (including preinfusion) 70 seconds

Results

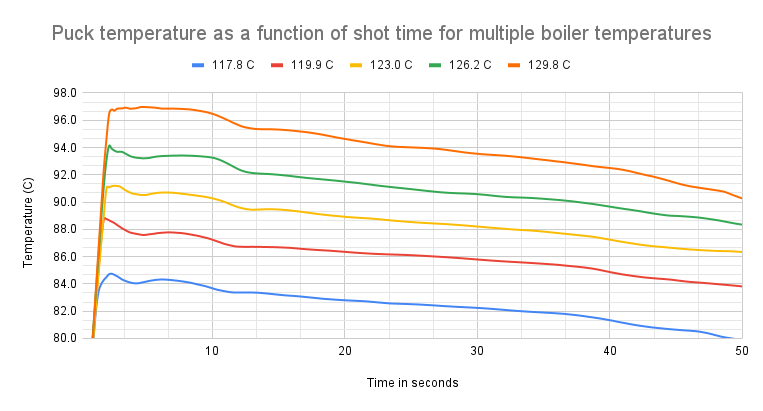

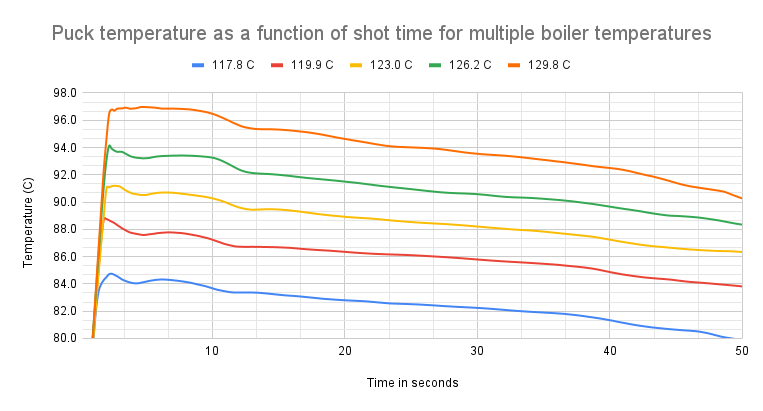

The graph below shows the temperature profiles at the puck during a 70 second shot (averaged from 6 Pulls) at 5 Setpoints that encompass the generally accepted range of brew temperatures for espresso. The method for obtaining and treating the data for the graph follows.

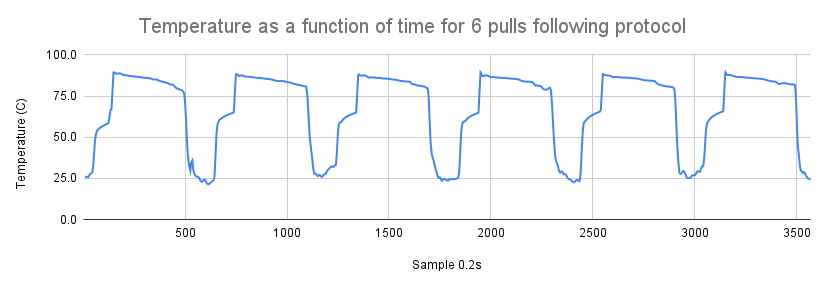

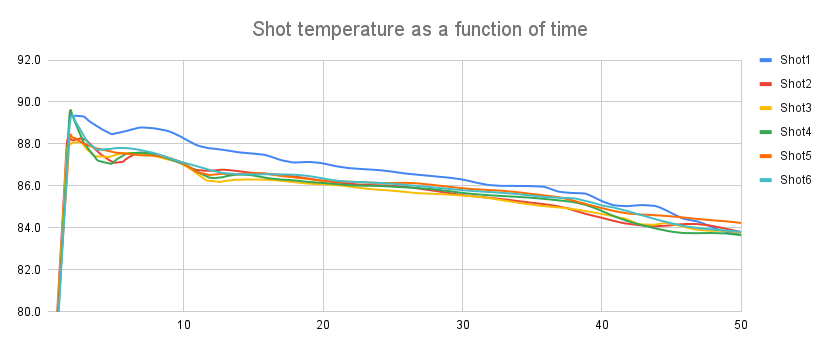

Temperature data was recorded for 6 Pulls at one Setpoint:

The period of 50 seconds starting from the moment the lever is pulled from the 6 individual shots was isolated and superimposed (everything after this period is not of interest as it is outside the window of extraction times for normal espresso shots):

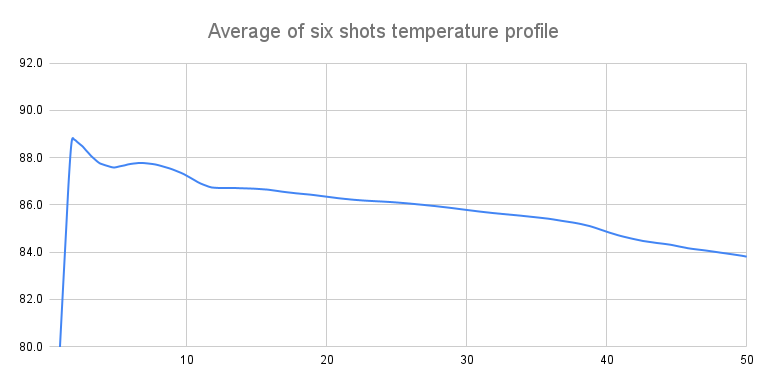

From those six shots an average profile is plotted:

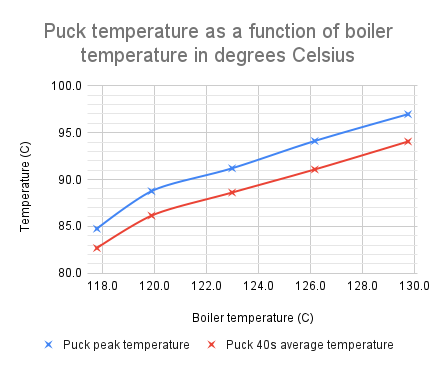

The graph above represents the thermal profile of the Lapera DS for a boiler temperature of 120°C (or a boiler pressure of 1 bar). Peak temperature at the puck is 89°C and the average for a shot time of 40 seconds is 86°C.

The process was repeated at multiple boiler Setpoints in order to characterize the relationship over the entire espresso brew temperature window. The window used for this experiment was from 85°C to 97°C. Expanding the experiment beyond the generally accepted range of 93°C +/-3 will show whether the relationship between boiler temperature and puck temperature can be approximated as linear within this range or whether the theoretical increase in heat losses at higher temperatures must be taken into account.

Temperature profile of the Lapera DS

The graph below shows the temperature profiles at the puck during a 50 second shot (averaged from 6 Pulls) at 5 Setpoints that encompass the generally accepted range of brew temperatures for espresso.

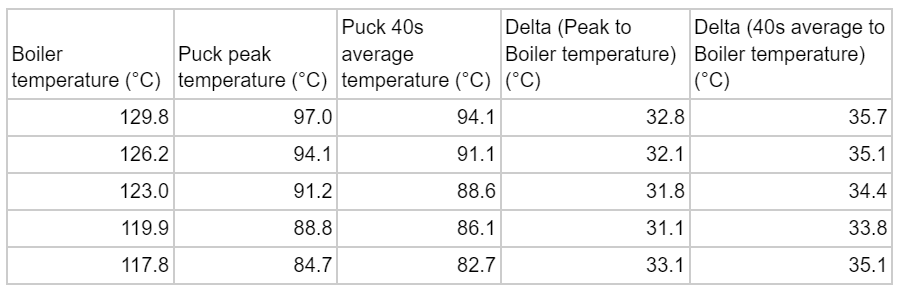

The following table shows the temperature offset (delta) between Boiler temperature and Puck temperature over the range of Setpoints:

From the table we can generalize the relationship between temperature at the puck and the Actual boiler temperature over the working range of boiler Setpoints:

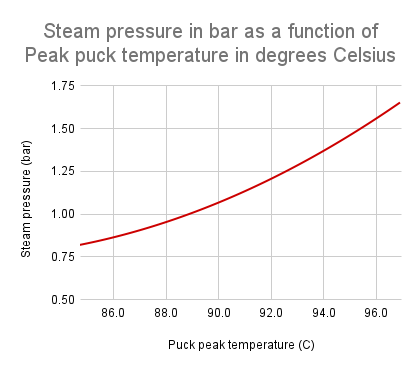

Another way to look at the data is to look at boiler pressure, which corresponds directly to boiler temperature and can be read directly from the manometer on the front of the machine.

Best-fit 2nd degree polynomial

Conclusion

First, while there is a lot of interesting data here, I don’t necessarily think that one should read too much into the numbers. Taste is and must always be the ultimate arbiter. After decades of experience with lever machines of similar design, I have “self-selected” a Peak temperature that is roughly 4°C below the “industry standard”. While not proof of anything, it suggests that a lower temperature works well with this type of design and the medium roast coffees that I generally prefer. It would seem plausible that lighter roasts that theoretically require more work to extract correctly would benefit from a higher brew temperature. In practice, we get good results from a range of coffees only adjusting the grind, dose and yield ratio. Anecdotally, some users have expressed a preference for brew temperatures / Setpoints at three or four degrees above the “factory settings” for very light roasts.

For existing Lapera users: Peak brew water temperature is on average 31.8°C lower than Actual boiler temperature for any given Setpoint. However, due to a number of factors including variation in the combinations of sensors and thermowells between editions, location of the sensor in the water column inside the boiler and variation between sensors themselves, the Measured boiler temperature (the temperature measured at the sensor inside the boiler used to achieve the Setpoint) is not the same as Actual boiler temperature. All Lapera machines manufactured have been adjusted to a known pressure/temperature while they were on the test bench. Using this data, it is theoretically possible to calculate an exact offset on a per serial number basis. (Of course we have done this – just ask us if you want to know yours). For the future, the offset could be integrated into the firmware so that the displayed temperature matches the Actual boiler temperature. In the same vein, the display could also be used to show theoretical brew temperature in addition to boiler temperature. I am somewhat reluctant to do this for a number of reasons. First: because it would be an indirect value (i.e. a calculated value as opposed to one that is directly measured) based on a single piece of calibration data taken when the machine is brand new. Regular calibration would be required to ensure its continuing validity. Secondly: I caution against a purely data-driven approach to coffee in general, and specifically one based on an industry standard that is tailored to pump-driven machines with E61 derivative groups because spring-driven levers have significantly different thermal and hydraulic characteristics.

As a generalisation, a pressure reading of 0.8bar on the manometer on the front of the machine should be considered the low end of the brew temperature range, and 1.6bar the extreme high end. We recommend a general setting of 1.0 bar for most dark to medium roast level coffees and a maximum of 1.25 bar reserved for extremely light roasts. All of these recommendations are, of course, subject to the taste in the cup.

As part of the larger discussion of temperature profiling: it is relatively well known that spring-lever machines deliver a pressure gradient (starting high and finishing comparatively lower at the end of the extraction) because the spring provides more force at maximum compression at the top of the piston stroke and a diminishing amount as it expands while pushing the water through the puck. It is perhaps less well known that lever machines can, and in the case of the Lapera DS do, also deliver a temperature gradient.

The generally accepted explanation for the benefits of a declining pressure profile is related to puck degradation and flow rate. The puck degrades as the brew water carries away fines as it passes through it. As the puck erodes, it provides less and less resistance to flow. A constant pressure source results in increased flow over time as the resistance decreases. The consequences of this are, firstly: a higher risk of channeling as the shot progresses and secondly: the potential for over-extraction of undesirable soluble compounds towards the end of the shot. A constant flow or a declining flow mitigates the risk of channeling and would also be beneficial if the desirable solubles are extracted early during the shot as opposed to later on. There are a number of studies that point to this being the case, and intuitively it seems plausible.

Conjecturally, given that the compounds that are being extracted are more soluble at higher temperatures, a declining extraction temperature profile would be desirable for the same reason, i.e. that a declining temperature profile would extract less of the undesirable compounds present later in the extraction.

All in all, the combination of declining pressure and declining temperature profiles present in spring lever machines in conjunction with reasonable temperature stability probably goes a long way to explain the reputation of lever machines as being “forgiving”. In the opinion of this admittedly biased machine designer, it is not that lever machines are forgiving, it is rather that 9 bar machines are unforgiving because constant pressure just isn’t the right way to do it! I also find it telling that the industry has put a great deal of effort over the past 10 to 15 years into pressure profiling. Maybe, just maybe, the pre-E61 lever designers were on to something?

______________________